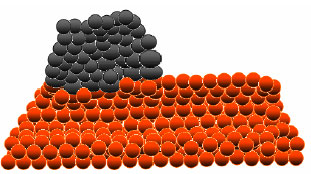

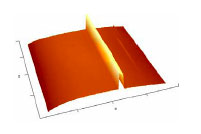

In this research program, we develop innovative processes to generate nano-coatings. We further investigate mechanisms of tribochemical interactions on surfaces of metals and oxides. Fundamental investigation focuses on new phenomena and non-equilibrium surfaces, including surface forces and wear from nanometer to centimeter length scales, new surface bonds, nonequilibrium crystal structures, non-stoichiometric products, and kinetics of growth. Experimental approaches include using atomic force microscopy (AFM) and table-top tribometery to polish, manipulate, and test materials at different length scales. The primary methods of surface characterization include AFM, TEM, XPS, TOF SIMS, and other high-resolution spectroscopic techniques. Materials studied are strategically selected to reveal principles in effects of electronic, chemical, and crystal structures on friction and wear. This research is at the interface of several scientific and technological areas involving physical, chemical, mechanical, and tribological properties of advanced materials. The outcome of this research is in the development of novel nanostructured materials and nanofabrication processes.